Quality control is a critical and high-importance step for many industries, as potential defects can cause significant expenses, quality loss, and possible danger to health and safety. From 2004 to 2016, the costs of defective product recalls reached approximately 50 billion USD. Later, in 2019-2020, the defective Takata airbags became the reason for the recall of millions of vehicles due to the danger of explosion. Defects in manufacturing, food markets, electronics, buildings, and many other industries could cause serious losses. It underlines the importance of accurate and reliable quality control.

While traditional quality control methods like human visual checks are limited due to human factors, AI defect detection can offer more accuracy, reliability, and efficiency. AI-based detection is highly adaptable to various defects in growing industries. Today, we will review the AI's role in the detection process, the technologies behind the procedure, the challenges, and the case study.

AI in Defect Detection: The What and Why

Artificial intelligence can empower defect detection by identifying defects and anomalies in products, components, or systems during the production or final stage of quality control. Machine learning technology, computer vision, and various automated solutions significantly enhance detection accuracy. As a result, they lower the risk of imperfections or potential danger for future users.

Here are the challenges for traditional human defect detection:

Traditional detection systems can be the source of many errors related to missed defects or false rejections. AI learns from historical data and focuses on minimizing errors and improving quality. By using ML and CV technologies, AI excludes traditional inefficiencies and limitations. As a result, it offers less time-consuming and more reliable, scalable options.

Benefits of AI Defect Detection

At Requestum, we believe that AI can transform the entire defect detection process, making it simpler and more reliable. We would like to underline three main benefits that mean the most to the industry.

Quality improvement

Compared to traditional methods, AI can offer high precision when identifying even the smallest defects. The working period and the amount of processed products do not affect the quality of the procedure. As a result, the end customers get high-quality, free-of-defect products that improve customer satisfaction and build trust and loyalty to the brand.

Real-time detection

If traditional methods may need batch-after-batch processing or manual review, AI systems can provide the checks right in manufacturing. The AI-powered approach enables immediate feedback. It allows manufacturers to fix the issues instantly and minimize the waste. Simultaneous control prevents possible defect escalations, which is crucial for industries where quality control means safety to users like electronics, pharmacy, or automotive.

Cost and time efficiency

AI manufacturing defect detection reduces check time and related costs thanks to the ability of automated systems to streamline the process and reduce the need for extensive human manual labor. The reduction of human errors leads to the reduction of potential recalls and additional reproduction caused by defects. Also, it makes the whole production cycle faster. Detecting defects in the early stages of processing helps to avoid further consequences like warranty claims, legal liability, or harm to the brand's reputation.

Technologies Behind AI Defect Identification

Let's take a look at the technologies behind AI-powered detection of defects and discuss how they can help.

Computer vision defect detection

Computer vision, or CV, is the area of artificial intelligence responsible for visual world interpretation. Simply put, a CV helps AI detect, analyze, interpret, and understand information from various visual sources. It includes cameras, video, images, and other visual suppliers. With deep learning models, CV can accurately identify and classify visual elements.

CV provides image acquisition by capturing the images of products during production. The received images are enhanced to make the relevant features more visible for further extraction. CV identification helps to detect patterns and textures within various dimensions. Pre-trained ML models compare the extracted features with set patterns of correct items to mark any anomalies. Then, the automated system sorts out the potentially defective parts and can even send a notification for additional manual inspection.

Discover how AI can optimize maintenance efforts

Machine Learning for detecting complex defects

Artificial intelligence simplifies defect detection using machine learning models, so let's review the most widespread options and what they can offer.

CNN (Convolutional Neural Network)

This deep learning model is focused on image analysis with pattern understanding on a pixel basis. Recognizing various shape and texture anomalies, CNN can identify cracks and scratches.

RNN (Recurrent Neural Networks) and LSTM (Long Short-Tem Memory Network)

AI can analyze vast amounts of temporal data to identify defects during continuous production. The model can detect product anomalies such as textiles and wires through sequence analysis and sensor reading.

Autoencoders

This machine learning model is useful for the detection of unusual defect types. Learning the features of the provided standard examples, AI can mark products that do not match the required pattern for further inspection.

GANs (Generative Adversarial Networks)

GANs are helpful during AI model training as they can generate data to simulate various scenarios for detecting non-common defect types. GANs create the possibility for all-covering model preparation and enhance its detection potential.

Machine learning techniques and deep learning models enable more accurate and faster defect detection with a lower chance of mistakes or false positives. AI-powered systems with adaptive capability can easily adjust to new types of defects without the need to be reprogrammed according to changing conditions. Defect detection using machine learning technology is more reliable for long-term manufacturing thanks to its ability to detect even the slightest mismatch with required patterns and standards.

Sensors

The combination of data received from various sensors (including thermal, acoustic, and ultrasonic) and AI algorithms helps to detect internal and even hidden defects that are not visible to the human eye.

Real-time processing

Cameras and inspection machines can integrate artificial intelligence to process products in real-time. This approach allows manufacturers to exclude the cloud connection and instantly get results.

Importance of AI-based Defect Detection for Businesses

AI-powered defect detection can offer significant advantages to businesses within various industries by improving efficiency, reducing costs, and helping maintain a high-quality level. We have prepared a small insight into AI's impact on some major industries.

Retail

AI-based defect detection helps to ensure that only high-quality products that fully match the required standards can reach the customers. Imperfection detection in the early stages prevents defective products from being stocked in the inventories. As a result, a company with checked and defect-free products can build better trust and loyalty of the customer to the brand, which is a crucial factor for a competitive market.

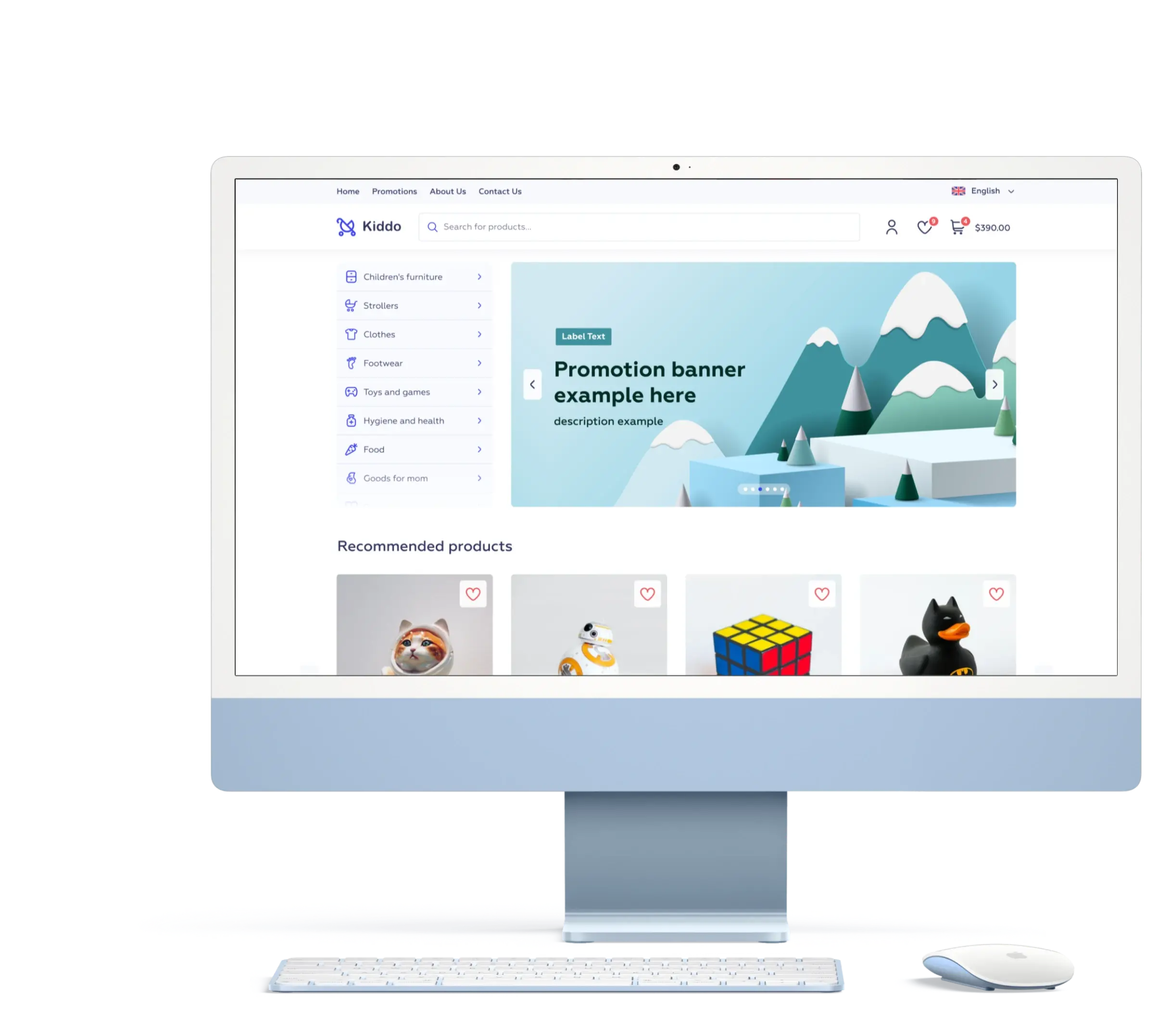

Multilingual B2C eCommerce Platform for Children's Goods

Manufacturing

Automated defect detection in manufacturing can cut the time required for inspection, replacing manual checks with automated solutions and speeding up the entire production process. In electronic manufacturing, AI can also provide checks to identify defects in circuit boards, components, assemblings, or housing to ensure that future products match specifications and required safety regulations.

It enables quality assurance and saves costs by minimizing potential waste, rework, and downtime. AI's ability to adapt and adjust to the new design and features within the product line ensures stable defect detection without additional training.

Utilities

Artificial intelligence identifies defects in equipment like pipelines, power grinds, or machinery. It helps to take action before it could cause any potential damage. It also lowers the need for further reparation and interruption caused by service maintenance. It leads to safer operation and protects staff and customers from possible danger. AI predictive capabilities can also analyze potential equipment failures and help to apply maintenance in time.

Transportation

Safety is critical for the automotive industry. AI's ability to detect defects in frames, engines, transmission, and car bodies can significantly improve customers' protection by preventing potential accidents. AI can further detect imperfections in transportation networks like roads or railways. To ensure safety, it can mark the parts with risk factors and defects like cracks or wear.

Public sector

Companies working in the public sector can use artificial intelligence to detect defects in public structures like roads, bridges, and water supply systems, ensuring efficient infrastructure maintenance. With an AI-powered detection system, you can detect problems before escalation and avoid high-cost repairs. As a result, customers can expect reliable service delivery free of potential hazards and issues.

Agriculture

Artificial intelligence within the food industry can help ensure the delivery of safe and high-quality products by analyzing and detecting imperfections in the products' visual, physical, and chemical states. It means that AI can identify bacterial presence, spoilage, or contamination.

AI can examine plans for diseases and pest damage in the agriculture sector to notify farmers, improve the quality of crops, and reduce potential losses due to insufficient harvest.

Artificial intelligence is heavily engaged in quality assurance and risk reduction within many industries. It reduces potential losses and the chance of rework and recalls, streamlines operating processes, and lowers the need for manual labor.

Our Experience in Implementing AI for Defect Detection

At Requestum, we have deep expertise in various areas of artificial intelligence use, including computer vision and machine learning technology. By leveraging advanced solutions, we can help companies arrange the process of accurate defect identification. Thanks to our AI-powered approach, you can ensure your clients get top-quality products. So, what can our experts offer for your business?

Integration with the existing system

Our expertise allows us to integrate AI-powered solutions into your existing system easily and accurately. By combining computer vision, high-resolution imaging tools, and machine learning frameworks, we help empower the current defect detection system, leveling it up to the new quality stage. TensorFlow and PyTorch open-source frameworks enable AI development and integration into various environments, customizing it to your needs.

Adaptivity and customization

We understand that each industry and business has specific detection requirements and needs an individual approach. So, we are heavily focused on adding customizable features to our solutions. We train models for the defects relevant to the specific products, for example, surface cracks, misalignments, functional failures, or whatever is required for your field of business. With AI continuous learning, models can adapt to inevitable changes in production, considering new product features, designs, and defect patterns.

Case study spotlight: fabric defects detection

We created an automated tool for fabric defect identification during our work on the Fabric Defect Detection project. Our mission was to develop a reliable automated solution that recognizes imperfections during polymer composite material production. Our client focused on delivering outstanding products and wanted to minimize waste and make the manufacturing procedures more efficient.

We have trained the machine learning model on the diverse database of fabric defects and applied U-net architecture and TensorFlow framework to create a tool to detect and segment fabric imperfections.

Overcoming Challenges in AI Defect Detection

Integration comes with new possibilities and challenging tasks, so sharing advantages and the most common challenges you may face is important.

Quality and diversity

-

Challenge: AI models heavily rely on the data provided for training, and their quality and diversity directly impact the efficiency of the future defect detection system.

-

Solution: The training dataset should contain a wide range of possible defect types, different materials, conditions, and operation scenarios to cover as many situations as possible. Supply the training model with close-to real-world conditions to ensure it will operate well in a changing environment.

Interpretation issues

-

Challenge: Sometimes, understanding AI-powered decision-making can be challenging, but it is crucial for your business to know how it operates and what lies on the basis of its decisions about defects.

-

Solution: Our experts believe the easiest way to deal with it is to develop an insight function to help AI explain the grounds for any particular decision and enhance the trust and simplicity of AI integration into a usual workflow.

Scalability problem

-

Challenge: Integration within several product lines or locations requires serious planning and can cause integration issues due to incompatibility.

-

Solution: We apply seamless deployment and scaling with the help of Docker and Kubernetes technologies to achieve smooth integration. With careful, reasonable planning and reliable resources, we choose optimization solutions that can reduce the size and offer scalability capabilities for the future. Also, regular monitoring and adjustments will help to adapt systems according to the changing needs of growing production.

Adaptability to dynamic environments

-

Challenge: Manufacturers often have changing, dynamic environments, variable lighting conditions, various materials, and different production speeds.

-

Solution: We are focused on AI-powered model creation, which could consider changing environmental conditions and will be able to adapt according to different needs while maintaining the same level of performance. We fine-tune pre-trained models to react to new data for quick adaptation and implement systems for continuous learning. It will help the model to evolve during the training and future operations.

Need expert help to achieve your goals?

Costs and return on investment (ROI)

-

Challenge: The AI implementation can be a costly procedure due to hardware, software, training, and integration expenses.

-

Solution: First of all, remember that such an update to your manufacturing defect detection will save a lot of costs in the future, thanks to reliable quality checks and defect-free products. You can start with a small implementation to see the effectiveness and evaluate the solution's effect on your business. You can also combine AI-powered tools with traditional methods to reduce costs.

Future of Defect Detection with AI

According to the predictions, the defect detection market can grow to 5.5 billion USD by 2032. Such an estimation shows how much current defect detection systems influence quality control within industries, and we believe that in the future, this effect will only grow and bring more possibilities and advantages.

Continuous development in AI will help new detection systems become even more precise, accurate, and productive during defect identification, catching even the smallest imperfections. The combination of computer vision, machine learning, the Internet of Things, and variable augmented reality solutions can help to develop monitoring systems for data collection and analysis on an entirely new level.

Conclusion

AI defect detection is an advanced solution that empowers current defect identification systems, ensures high quality, streamlines industries, and helps supply customers with safe and reliable products. As you can see, it has crucial meaning for retail, manufacturing, food, public, and many other industries, proving its efficiency in the processes and the final results. If you are looking for a solution to improve your defect detection process, we believe that AI can be exactly what you are looking for, as it can offer better precision than manual work could ever have. And if you have any questions or need help with AI solution development, feel free to contact us.

Our team is dedicated to delivering high-quality services and achieving results that exceed clients' expectations. Let’s discuss how we can help your business succeed.

SHARE: